Application: High Recovery Mining Water Reuse

Problem: Booster pump maxed out, low flow in 4th and 5th stage, scaling/fouling

Customer: Osmoflo

Background

Osmoflo, an OEM based in Australia, had a 5-stage mining water reverse osmosis skid with major operational issues they couldn’t solve, until the discovery of reverse osmosis elements from Aqua Membranes with printed spacer technology®.

Osmoflo’s reverse osmosis skid was designed to reuse water from the mine and ultimately save water. Unfortunately, it struggled to reach its full potential, often getting 85% of the water cleaned instead of the intended 90%. The water coming in was tricky, with high levels of ammonia and copper and a pH of 9 to 9.5, causing frequent clogging and short membrane life. This caused low crossflows in the 4th and 5th stages even with a booster pump often running at maximum speed. It was time for an improvement, which meant either more equipment or new technology with a unique solution to their problems.

The Upgrade

Osmoflo installed new Aqua Membrane elements in the 4th stage of AdChem’s treatment process in December 2023, replacing the old mesh elements from an industry leader. Upon replacement, they found positive results achieved with Printed Spacer Technology®.

Results

After installing the Aqua Membranes, several improvements were noticed:

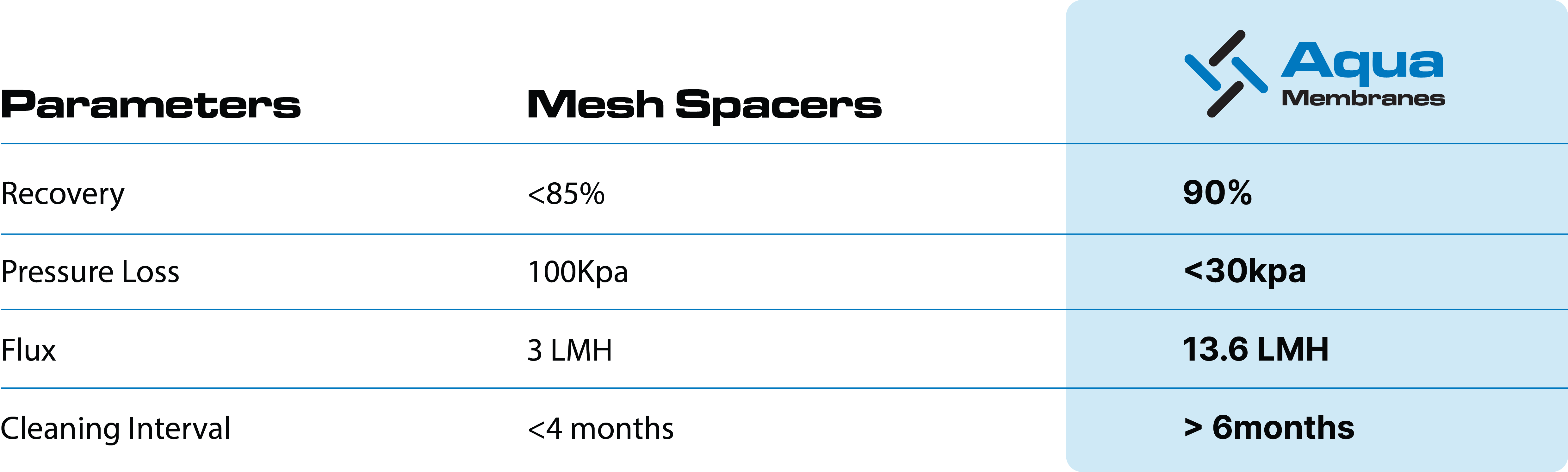

- Significant Pressure Loss Improvement: The pressure difference across the membranes dropped from 100 kPa to less than 30 kPa, showing that the new membranes with printed spacers remove much of the system’s wasted energy.

- Better Water Recovery: The plant’s recovery rate improved from 85% to 90%, reducing the amount of water down the drain by 33%.

- Higher Flow Rates: The water flow rates through the membranes increased significantly, from 3 liters per hour per square meter (LMH) to a range of 10-15, depending on the incoming water quality.

- Membrane Life Improvement: Upon installation, they hoped to see a six-month improvement without a changeout. Printed Spacers hit six months and kept on pushing, now approaching a year with little sign of slowing down.

“3D Printed Spacers are a brilliant, novel innovation that unlocks new opportunities for system operators like us to minimize waste streams, maximize water recovery, reduce energy consumption, and keep our customers happy. They’ve passed the tests we’ve put them through at AdChem, and I can’t wait to see what else they can do!” – George Britten Jones, Osmoflo Process Engineer

Conclusion

Installing Aqua Membranes in this mine water reclamation system for Osmoflo has led to significant performance improvements that have helped Osmoflo solve its operational issues by swapping only membrane elements.

This includes higher water recovery rates, increased permeate output, and longer membrane element life – all achievements other membranes couldn’t deliver. These advancements demonstrate the effectiveness of Aqua Membranes technology and make Osmoflo an industry leader in membrane systems with printed spacers.

Osmoflo’s open approach to solving their problems sets a strong example for similar facilities aiming for better water savings, energy savings, and operational improvements. Osmoflo has Aqua Membranes in the 4th stage and is now using Aqua Membranes AM-BW505-ECO1.0 in the 5th stage.

Learn more about our products, download a .PDF of the case study, or contact our team to discover the impact of our technology.