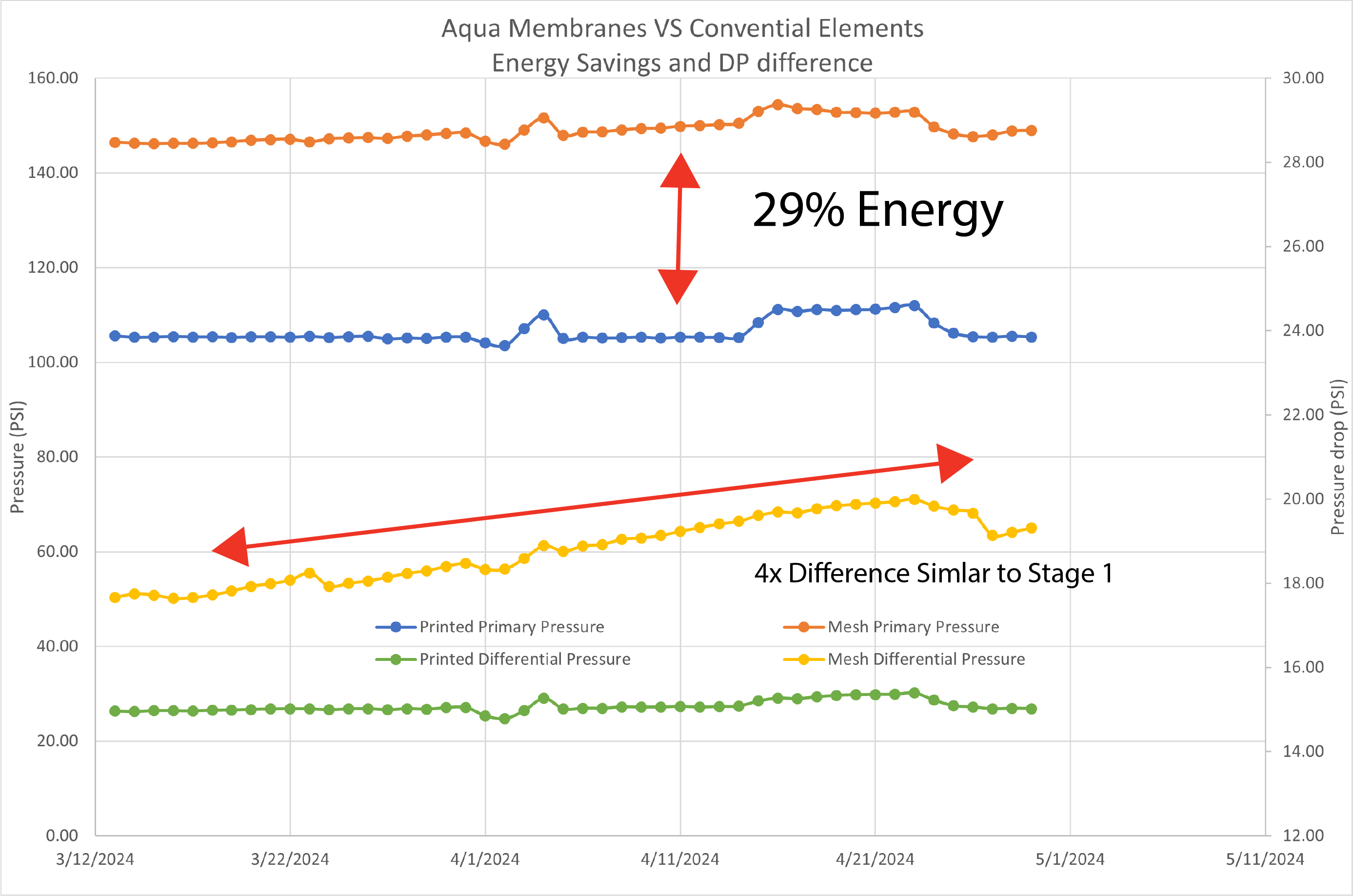

Project overview: Aqua Membranes saves 29% energy and Lasts 4X longer than Industry Standard

Location: Micron Boise

Application type: UPW Wastewater RO

The semiconductor industry produces over a trillion memory chips annually and can require as much as 2,200 gallons per chip of ultra-pure water (UPW) in the manufacturing process. Ultra-pure water eliminates the chance for contaminants to contact the chip’s surface, preserving the quality of the finished product. The production of UPW can consume massive electricity, so by increasing the efficiency of reverse osmosis membranes used in UPW production, companies can reduce their energy use and cost.

Micron Technology targets energy use reduction to reach decarbonization goals

Micron’s 2030 sustainability goals include a 42% reduction in direct greenhouse gas emissions, a 75% water conservation rate and a 95% reuse, recycling and recovery rate for waste, with an aspiration to achieve zero hazardous waste to landfill. The company faced a significant challenge in its UPW/wastewater treatment systems that can use millions of gallons of water daily, high energy demand and limited membrane life for RO systems. To help the company meet its greenhouse gas emission reduction, water conservation, waste

reduction and energy efficiency goals, Micron needed a better solution for its water treatment processes.

The Solution: Printed Spacer Technology® from Aqua Membranes

Unlike typical mesh feed channels, Aqua Membrane spacers are 3D printed directly on the membrane, taking up far less space and eliminating the need for the spacers to be connected to one another. Because these spacers are optimally spaced and occupy significantly less volume in the feed channel, fouling and scaling from spacer to spacer are minimized, slowing the rate of bulk fouling and reducing pressure drop.

A slower rate of fouling allows for longer intervals between cleaning, which results in lower maintenance costs and longer membrane life. A reduction in pressure drop results in greater energy savings and reduced emissions. Customers using reverse osmosis with Aqua Membranes technology waste less membrane supply, labor, energy and water, all of which improve profitability and sustainability.

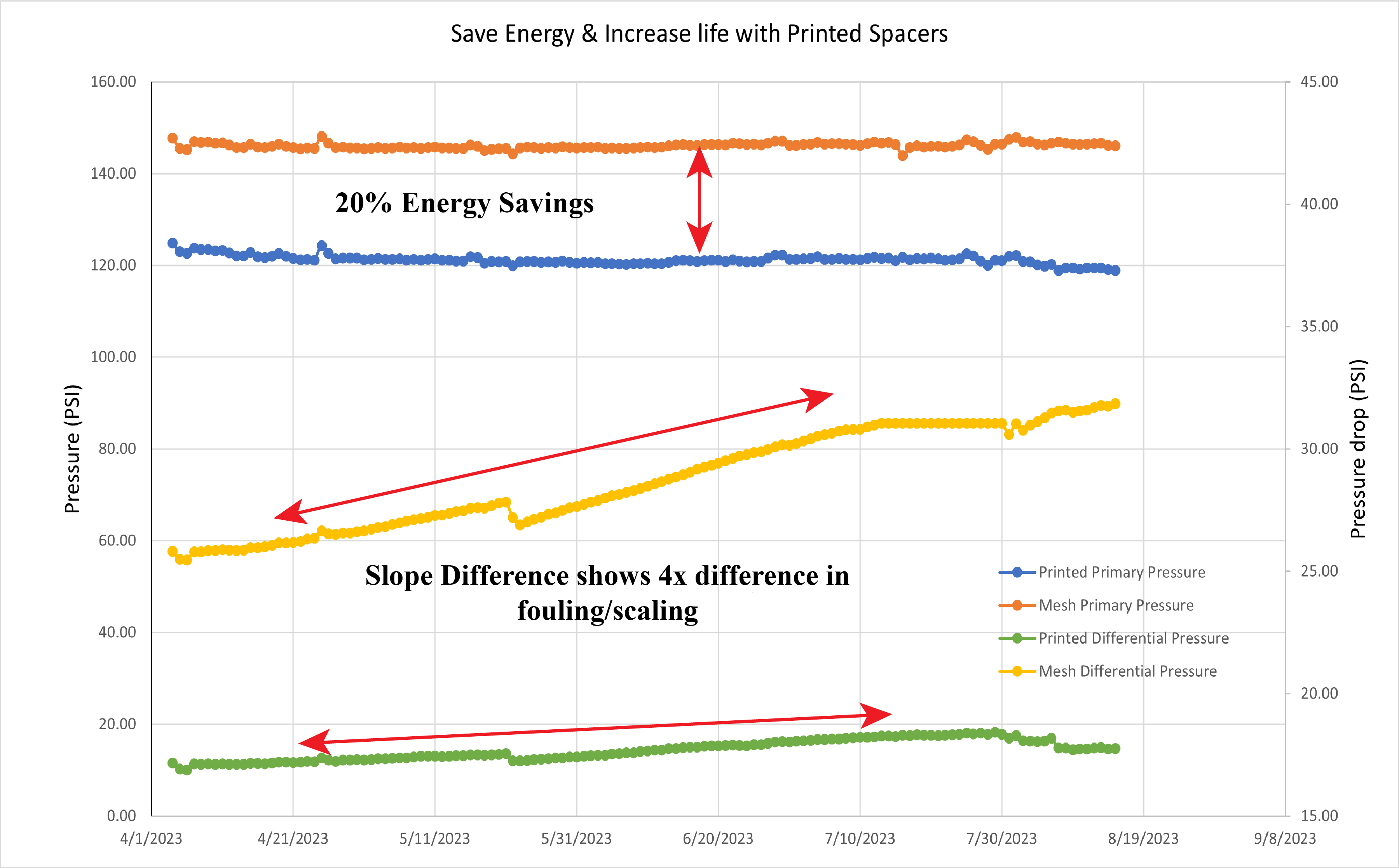

Results: Two Stages of Testing

In Stage 1, baseline establishment testing revealed dramatic reductions in both the fouling of the membrane and the use of energy. This system ran continuously 24 hours per day from April 2023 through January 2024.

- Fouling Reduction: The printed spacers reduced the rate of differential pressure (DP) increase by 4x

compared to mesh spacers, indicating significantly less fouling. - Energy Savings: Initial tests showed a 19% energy reduction, increasing to 22% over a year.

“Data doesn’t lie, and data like this shows the massive benefit of printed spacers,” said Andrew Byrnes, from the Micron Ventures team.